Lin-Gas Industrial & Commercial Applications

Power your business with Lin-gas propane!

Lin-gas Propane TankThe industry and technology of the propane business has changed significantly over the past 20 years, and customer demands have become more individualized. No longer are customers satisfied with a “one size fits all” program. They demand service that is 24 hours a day, 7 days a week.

At Lin-gas, we run hard and fast to deliver commercial propane services and propane products better, faster and safer. The training of Lin-gas employees is rigorous and constant. We understand our responsibilities and are committed to anticipating and exceeding our customer’s expectations. Power your business with Lin-gas.

Why Propane instead of electric, gasoline or diesel?

Economical: Propane forklifts offer an economical way to meet material handling needs. Propane forklifts have lower life-cycle costs than electric, diesel or gasoline-powered forklifts.

Low Maintenance: Propane produces fewer engine deposits than gasoline and diesel fuel, resulting in lower maintenance costs. Propane engines can typically last up to twice as long as gasoline engines.

Environmentally Friendly: Propane is a non-toxic, clean-burning fuel that is safely used to power forklifts indoors and out. There is no spillage loss or evaporation into the atmosphere.

Safe: Propane forklift tanks, fuel lines and carburetion components meet or exceed strict specifications. Built-in safety devices automatically shut off the flow of fuel in case of an accident.

Versatile: Propane forklifts can be used in indoor and outdoor applications. Propane cylinders can be stored and moved almost anywhere within a work site.

Strong: Propane forklifts maintain consistent, 100-percent power throughout operation. They have the ability to push heavy loads at full capacity, up and down inclines, faster, and for a longer amount of time than electric forklifts

Long-running: Propane forklifts with a typical 33.5 lb cylinder run an average of 8 hours between refueling.

Simple & Fast Refueling: With propane forklifts simply remove the empty cylinder and replace it with a full one. Refueling can be completed in 5 minutes.

Propane Cylinder Exchange

Lin-Gas offers a cylinder exchange program for your forklifts, buffers, and material handling equipment. WE have 5, 10, and 8-gallon (w.c.) steel or aluminum cylinders. Storage cages for your cylinders, in compliance with OSHA and agency requirements, are available for sale or lease.

We use state-of-the-art proximity filling devices to be certain that your cylinder is filled to exact tolerances.

Lin-Gas maintains a rigorous inspection and safety maintenance program on all cylinders, so you have the confidence that the equipment you are using is safe and in compliance with applicable laws and regulations.

Lin-Gas has a number of price protection programs and contracts available so that your company can budget expenses and avoid the volatility pf the petroleum market. All propane is HD-5 specification and is injected with LG – 70 or similar additive to ensure maximum performance and complete combustion to minimize emissions.

LG – 70 Propane Additive

All Lin-gas propane provided for use with material handling equipment (forklifts, scissor lifts etc) is injected with LG – 70 which improves the burning characteristics of the propane gas engine for better performance and economy. The detergent-like additive helps to remove and prevent harmful engine deposits. This improved engine performance can improve emissions, help reduce carbon monoxide and extend the time between maintenance intervals.

Filtered Propane

Lin-gas, Inc. purchases only HD-5 Propane. To provide that extra level of quality assurance to our motor fuel customers (propane powered forklift trucks and scissor lifts etc) we filter every gallon of motor fuel propane to ensure that any impurities that may have occurred during the transportation of the propane, is removed before our forklift cylinders are filled at our plants before delivery to you. We continue to review technologies to be certain we have the very best quality propane.

If you are interested in more information on any of these subjects please let us know and we can provide you with a comprehensive report detailing this process & it’s benefits.

Cylinder Safety Features

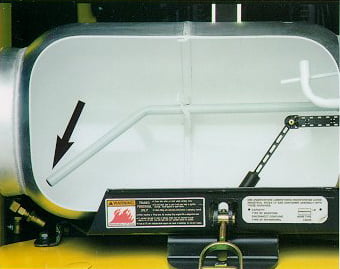

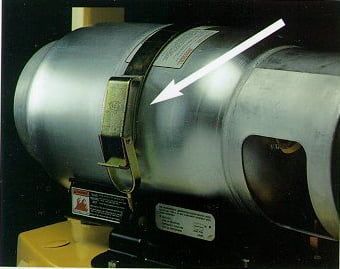

The locator pin in the locator hole restricts the movement of the cylinder. This decreases the wear and tear on the hose and connection fittings.

When the cylinder is positioned correctly, should the relief valve open, the propane would expel away from the driver. This propane release would be vapor, which reduces the amount of propane release.

Having the locator pin in the locator hole correctly assures the user the liquid dip tube is in the proper position (bottom of cylinder) to withdraw liquid from the cylinder. This is essential for proper engine use.

Proper Forklift Truck Installation

(1) Find the locator pin on the bracket.

(2) Find the locator hole on the cylinder.

(3) Place the bracket locator pin in the cylinder locator hole.

(4) Tighten the bracket.

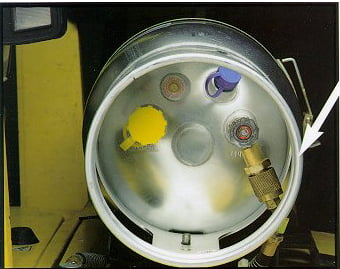

(5) Connect the propane fitting until it is firmly connected, leak free (no tools required) open valve and start engine.